A Brief History Of Woodworking

Strictly Woodworking

Let’s take a look at a brief woodworking history from past to present and see how it evolved through the centuries.

PLEASE NOTE: This post contains affiliate links, meaning I get a commission if you decide to make a purchase through my links, at no cost to you. Please read my DISCLOSURE for more details.

Wood is durable and is capable of lasting for centuries in sheltered environments. Excessive heat, light and moisture, not to mention termites and various insects do pose a threat to its longevity as natural bio-degradation under those conditions is inevitable.

Despite exposure to the elements, wood has been the principal construction material in the past and is still an important one in the present. It actually was one of the first materials to be used by our ancestors. Along with mud, stone and various animal parts, wood was always used as construction material and over the ages, it was also turned into various tools.

Woodworking In Prehistoric Times

The skill and the process of carving something from wood or building products using wood or as the primary material is called woodworking. A woodworker is someone who builds a variety of products that are made outof wood (or synthetic wood materials). Woodworkers can also be called carpenters.

As the human civilization developed, so did the tools. One of the earliest examples of wooden tools are the Schöningen Spears, which are a set of eight wooden throwing spears from the Paleolithic Age, estimated to beover 300,000 years old.

These wooden weapons for hunting and other flint tools for carving show that primitive people were already knowledgeable on how to create materials that would help them obtain their needs.

There are two ancient civilizations that are often mentioned when woodworking is the subject matter. These are the Egyptians and the Chinese. This is because woodworking has been shown in their ancient sketches and drawings.

Woodworking In Ancient Egypt

A vast amount of Egyptian furniture like chairs, tables, beds, stools and chests have been encased intombs. Preservation of such materials shows that the ancient Egyptians were inclined to use wood. Coffins that were located in the tomb were also out of wood.

Egyptians used varous metals for their woodworking endeavors. Copper and bronze were the main tools for woodworking. These were turned into adzes, pull saws, axes, chisels and bow drills.

Ancient Egyptians were the first civilization to do veneering. They were also the first to use varnish, therefore resulting to what is now termed as “finishes.” They used native acacias and the wood from the sycamore and tamarisk trees.

Woodworking In Ancient China

As for the Chinese, woodworking was said to have started when Lu Ban and his wife Lady Yun brought the plane and chalk line to China. This was during the Spring and Autumn period. From then on, Lu Ban’s teachings were said to have been recorded in the book “Lu Ban jing 魯班經” or “Lu Ban’s classic”.

The book was in fact compiled during the Ming period 明 (1368-1644). In one version, a certain Wu Rong 午榮 is mentioned as the compiler of the text, Zhang Yanquan 章嚴全 as a redactor, and Zhou Yan 周言 as a revising editor.

The book is complete with elaborate descriptions of the necessary dimensions for building different kinds of furniture like tables, altars and flowerpots among many other things.

Woodworking In The Present

In modern times, woodworking is just as important and omnipresent as ever. With advances in modern technology, tooling and manufacturing processes, there were significant changes introduced in the woodworking industry.

For example, rechargeable power tools, specialized workbenches and computer aided manufacturing processes result in a faster, cheaper and more efficient production with significantly less waste.

Additionally, hand-crafted work, such as furniture, arts and even day-to day household items (bowls, soups, cups, etc.) are still highly sought and command significantly higher cost to the consumer than items from various metals, glass, plastic or ceramic.

Various Properties of Wood

Axial Properties

Different woods have very different elastic, compression and torsion strengths. This fact was identified very early by our woodworking ancestors. Modern science tested it, confirmed it and quantified it.

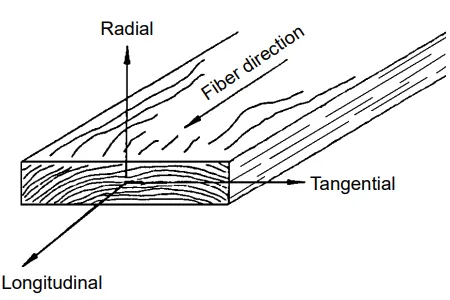

Wood is an orthotropic material; that is, it has unique and independent mechanical properties in the directions of three mutually perpendicular axes:

- The Longitudinal Axis - parallel to the fiber or the grain of the wood.

- The Radial Axis - perpendicular to the grain in the radial direction.

- The Tangential Axis - perpendicular to the grain but tangent to the growth rings

Elasticity of Wood

Elasticity implies that deformations produced by low stress are completely recoverable after loads are removed. When loaded to higher stress levels, plastic deformation or failure occurs.

Therefore, the modulus of elasticity determined from bending, rather than from an axial test, may be the only modulus of elasticity available for various wood species.

The elastic ratios, as well as the elastic constants themselves, vary within and between species and with moisture content and specific gravity.

Poisson's Ratio

When a member is loaded axially, the deformation perpendicular to the direction of the load is proportional to the deformation parallel to the direction of the load. The ratio of the transverse to axial strain is called Poisson’s ratio.

Poisson’s ratios vary within and between species and are affected by moisture content and specific gravity.

Rigidity Of Wood

The modulus of rigidity, also called shear modulus, indicates the resistance to deflection of a member caused by shear stresses.

As with the modulus of elasticity, the modulus of rigidity varies within and between wood species and with moisture content and specific gravity.

Commonly Used Woods

Examples of Soft Woods

- Bald cypress

- Cedar

- Douglas Fir

- Subalpine Fir

- Western Hemlock

- Western Larch

- Pine (various types)

- Redwood

- Spruce

Examples of Hard Woods

- Ash

- Aspen

- Balsa

- Basswood

- Yellow Birch

- Cherry

- Mahogany

- Maple

- Oak

- Walnut

- Yellow Poplar

Tools Of The Modern Woodworker

Measuring and Marking Tools

- Protractors, tape measures, rulers

- Scratch awls, marking knives, marking gauges

- Plane gauges in order to figure out how flatten the surface

- Hygrometers in order to figure out how much water the wood contains

- Various sizes of levels

- Winding sticks

- Combination squares, try squares, straight edges

Hand Cutting Tools

- The rip saw

- Cross cut saw

- Keyhole saw

- Bow saw

- Coping saw

- Tenon saw

- Gent’s saw

- Dovetail saw, etc.

Shaping Tools

- Hand planes like the smoothing plane, shoulder plane, spear plane, rabbet plane, scrub plane, blockplane and jointer plane.

- Jointer and thickness planer

- Router

- Rotary tools

- Gouges and chisels

- Drill press and Chisel mortiser

- Rasps

- Lathes

- Various other hand shaping tools like axes, draw knife and spoke-shaves

Power Tools & Equipment

- Power / Cordless Drills

- Dremmels

- Table saw

- Circular saw

- Radial arm saw

- Miter saw

- Band saw

- Scroll saw

- Hole saw

Finishing Tools

- Sandpaper to be used by hand

- Sandpaper for power sanders like belt sander, palm sander, orbit sander, disc sander or sanding blocks

- Steel wool or bronze wool to polish furniture and to apply stain

- Files and Scrapers

- Spray guns to apply lacquer

- Various brushes to apply varnish

Assembly Tools

- Screwdriver

- Mallets and Hammers

- Hand or power drills

- Various clamps like the F-clamp, G-clamp, C-clamp, miter clamp, bar clamp, band clamp and sash clamp

Accessory Tools and Furniture

- Workbenches

- Stools

- Safety Equipment (gloves, glasses, hats, boots, etc…)

Woodworking At Home

Today’s woodworker does not need fancy or sophisticated machinery or workshop in order to start and complete woodworking projects.

Modern tools and technologies allow most at-home woodworkers to set up shop for budgets as low as $500-$1000 as seen in the article How to Set Up A Woodworking Shop For Under $1,000. Go ahead and select the appropriate tools for your skills and situation if you have not done so yet.

Woodworking Resources Online

Woodworking Plans

Looking at a brief woodworking history from past to present would not be complete without referencing a few amazing online resources. Here are two of the more popular woodworking sites for further reference.

So, if you already have a workshop and tools, you can download a variety of woodworking at the sites below to start your new woodworking journey.

🔨 Teds Woodworking

Contains a massive collection of over 16,000 woodworking plans. Read our review here...

🔨 My Shed Plans

Contains another massive set of woodworking plans, with heavy emphasis on shed building. Read our review here...

🔨 Woodworkers Treasure Chest

Online Magazines

- WOOD Magazine is the world's most popular woodworking magazine and is a premier source forwoodworking info, shop-proven plans, tool reviews, and videos.

- Finewoodworking.com is a popular destination for experienced woodworkers who want to hone their skills further. There are various fine woodworking plans and projects to choose from on the site that also feature woodworking videos.